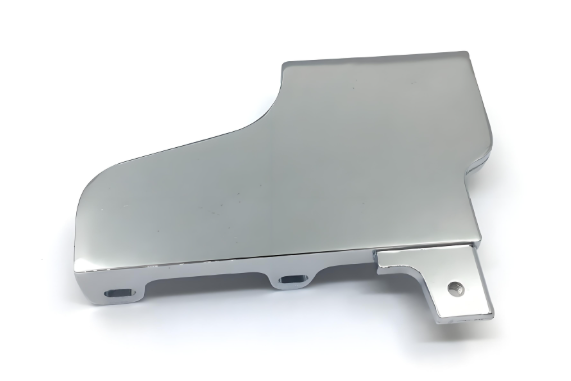

Product Description:

- 1.High precision - Excellent dimensional accuracy and thin-wall capabilities (as thin as 0.5mm)

- 2.Smooth surfaces - Naturally good finish (Ra 1.6μm achievable without machining)

- 3.Strength-to-weight ratio - Tensile strength up to 417MPa while remaining lightweight

- 4.Corrosion resistance - Superior to aluminum in many environments

- 5.Cost efficiency - Lower melting point (380-420°C) reduces energy costs vs aluminum

- 6.Ductility - Can withstand bending/forming better than brittle alloys

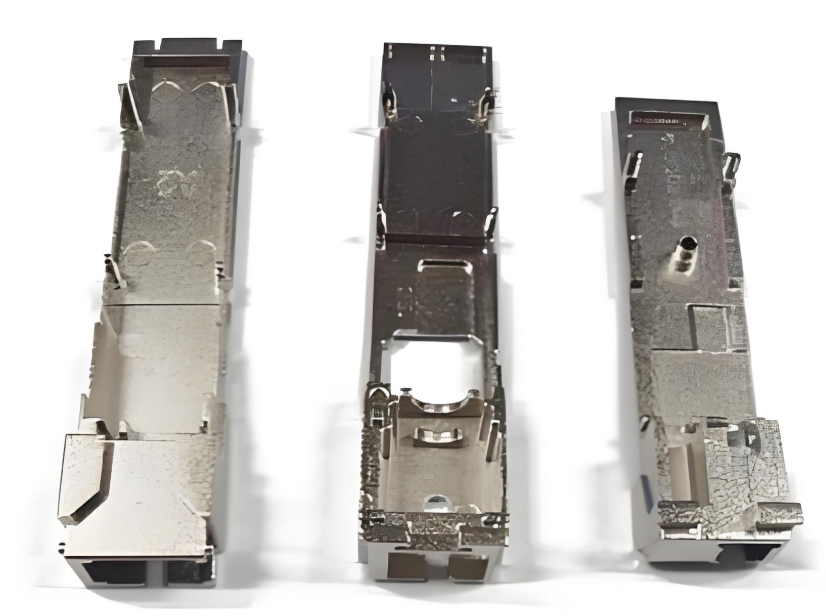

- 7.EMI shielding - Effective electromagnetic interference protection

- 8.Recyclability - 100% recyclable without quality loss

Common applications include automotive components, electronics housings, and hardware fittings. Popular alloys include Zamak 3 (most common), Zamak 5 (higher strength), and ZA-8 (best creep resistance). The process allows complex geometries with tight tolerances (±0.1mm typical).

545

545